We propose to transfer the entire unmanned aerial vehicle (UAV) production technology with the presence of our professionals for 1 year to help in organizing local production. As a result, you will have a ready-to-use UAV manufacturing with production processes provided and employees trained, which will be capable of manufacturing up to 300 units per year. The technology transfer process will consist of four steps.

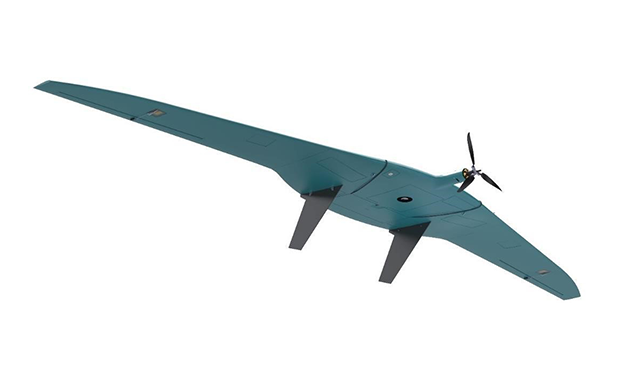

Fixed Wing UAV

Robust T-tail hybrid (battery & fuel) VTOL fixed-wing UAV, specifically designed for medium-area flight missions up to 100 square kilometres.

Commercial proposal for unmanned aerial vehicle technology

Copyright statement.

This description contains information that is the confidential & exclusive property of Nera-S.

This information shall not be copied, disclosed or used in whole or in part for any purpose whatsoever. Any use of this

information for any purpose without the written permission is strictly prohibited.

Step 1. Transfer of documentation.

1. We provide detailed description of the entire UAV manufacturing technology, a full set of the UAV design documentation, a list of the entire range of the glider components and the description of the feed materials for its manufacturing, with the procurement source description.

2. We provide the entire design documentation for accessories and auxiliary elements with a detailed description of the process for using said technologies.

3. We provide the requirements for the workshop premises and personnel qualifications and support with the process of selecting premises and hiring employees.

4. We provide wiring diagrams and description of UAV electronic elements with indication of their procurement sources.

Step 1 price: (20%)

Step 2. Organization of local glider manufacturing.

1. We provide the professionals who will help in the manufacturing organization, train the employees to work with composite materials, electronic components, software settings, and all UAV systems. The professionals provide support of local production for one year.

2. We train pilots in the UAV piloting principles, with subsequent examination and issuance of the official certificate from our company.

3. We manufacture 5 UAV complexes with one unit in the complex: 3 with video and thermal imagers, 2 with a camera for geodesy and cartography. These units will render the services and train pilots in parallel with the processes of organizing the manufacturing.

Step 2 price: (35%)

Step 3. Organization of local gyro-stabilized platform manufacturing.

1. We provide the entire design documentation of 2 gyro-stabilized platforms: one platform with a camera with a 30x zoom, the other with two cameras with a 10x zoom and a thermal imager.

2. We provide the process flow charts for manufacturing each mechanical element of the platform and the list of electronic components with indication their procurement sources.

3. We provide the key generator to the software for the autopilot and ground control station developed by us.

Step 3 price: (30%).

Step 4. Adaptation to the local market and support.

1. We adapt the UAV design to the peculiarities of the local area, select materials for manufacturing from the list of items produced domestically or by the nearest friendly countries.

2. We provide your engineers with all the necessary skills to develop the main elements, so that they can upgrade all the components and structures on their own in the future.

3. We undertake to provide full support and software updates within three years, with potential further extension.

Step 4 price: (15%).

Total price: USD 40,000,000

Payment procedure: 100% down payment by steps.

Information about existing manufacturing

1. Product price.

Sales price of one unit: USD 100,000-150,000

Cost of manufacturing of a single unit in case of 300 unit per year manufacturing:

Purchase price of materials and equipment: USD 9,350.

Salary: USD 890

Rent and administration expenses for the period of manufacturing a single unit: USD 500

Total: USD 10,740 is the cost of manufacturing one unit at the Russian manufacturing site.

Cost of manufacturing of a single unit in case of 1,000 unit per year manufacturing:

Purchase price of materials and equipment: USD 7,480.

Salary: USD 890

Rent and administration expenses for the period of manufacturing a single unit: USD 500

Total: USD 8,870 is the cost of manufacturing one unit at the Russian manufacturing site.

Marketing costs to attract a customer per unit: USD 500.

Customer training costs per one unit: USD 1,000.

Gross Margin from one unit in case of 300 unit per year manufacturing: USD 87,760.

Gross Margin from one unit in case of 1,000 unit per year manufacturing: USD 89,630.

Above calculation excludes the technology cost incurred.

2. Business model.

70% В2В

30% B2G

Key UAV applications in Russia include oil and gas industry, geodesy and cartography, agriculture, environment and nature management, security, electric power, construction, mining, and the industrial military complex.

Russian market volume at 2022-year end: USD 0.7 billion

3. Sales.

Over the last 3 years:

2020: USD 5m

2021: USD 13m

2022: USD 25m

2023: contracts for USD 25m have already been signed; the forecast value is USD 50m.

4. Number of employees, proposal and qualification.

The company currently employs 91 people:

Management: 4;

Manufacturing: 36;

R&D: 20

Testing: 6;

Quality: 5;

Service: 5;

Support: 4;

Back office: 6

5. Equipment price.

Cost of the equipment necessary for manufacturing 300 units per year: USD 1–1.5m.

Cost of the equipment necessary for manufacturing 1,000 units per year: USD 3–4m.

Equipment: CNC milling machines, CNC lathes, vacuum forming benches, drying furnace, press, tumbling equipment, plating equipment, 3D printer, plotter, forming matrices, and forming machine.

These can be acquired locally to save on export related costs